Thermal Paper Innovations: Enhancing Print Quality and Durability

The Role of Thermal Paper Innovations in Modern Industry

Demand for High-Performance Receipt and Label Solutions

The increasing reliance on thermal paper for receipts, labels, and tickets is primarily due to its quick and efficient printing capabilities. As sectors like retail and logistics expand rapidly, the demand for high-performance thermal paper solutions is escalating. This trend propels innovations that enhance the durability and performance of thermal paper. Studies indicate that businesses benefit from significant cost savings with these high-performance solutions, thanks to reduced printing errors and wastage. For instance, using thermal paper can eliminate ink and toner costs, leading to a more streamlined and economically efficient printing process.

Balancing Print Quality with Environmental Concerns

There is a marked shift toward eco-friendly thermal paper innovations, driven by rising environmental awareness among consumers. Traditional thermal papers often contain chemicals like bisphenol A (BPA), which have raised concerns regarding their impact on health and ecosystems. Consequently, the industry is now exploring alternatives that are both safe and sustainable. Empirical data shows that companies adopting sustainable practices in their use of thermal paper often enjoy enhanced brand image and customer loyalty. Businesses are increasingly recognizing that aligning their operations with eco-friendly practices not only addresses environmental concerns but also positively influences consumer perceptions, thereby fostering long-term success.

Breakthroughs in Thermal Paper Chemical Formulations

BPA-Free Developers: Pergafast™ and Eco-Friendly Alternatives

The introduction of BPA-free formulations such as Pergafast™ marks a significant advancement in thermal paper technology, addressing both print quality and health concerns. While traditional thermal papers often included Bisphenol A (BPA), which raised numerous health and environmental concerns, innovations like Pergafast™ provide safer alternatives. Comparative studies reveal that these eco-friendly options tend to outperform conventional thermal papers, offering not only similar print clarity but also enhanced safety for consumers and employees. Statistics from environmental agencies highlight the urgency and importance of migrating to BPA-free options, emphasizing their positive impact on public health.

Hybrid Bonding Technologies for Durable Imaging

Recent developments in hybrid bonding technologies have propelled thermal paper ingredients to a new level of durability and resilience. These technologies enhance the adhesion properties of thermal papers, leading to images that are both clearer and longer-lasting. The technical innovation in bonding ensures that prints remain sharp and legible, even in demanding environments. Real-world applications have shown that these improvements significantly boost the paper's resilience to adverse conditions such as moisture and abrasion, which is crucial for sectors that require reliable and durable documentation, such as logistics and healthcare.

Moisture-Resistant Coatings for Extended Shelf Life

Innovations in moisture-resistant coatings are pivotal in extending the shelf life of thermal paper by protecting it from environmental factors. Empirical evidence supports that these coatings dramatically reduce spoilage rates under ambient conditions, making them a game-changer for businesses that require long-lasting and reliable paper materials. Feedback from the industry indicates heightened customer satisfaction when products utilize these advanced coatings, highlighting the practical benefits and acceptance of these enhancements. Whether in retail, pharmaceuticals, or advanced logistics, moisture-resistant thermal papers offer a robust solution for maintaining document integrity over time.

Advancements in Thermal Paper Structural Design

Pre-Coat Layers for Heat Insulation and Smoothness

Pre-coat layers play a crucial role in enhancing the heat insulation and surface smoothness of thermal paper, which are key factors for quality printing. These layers help in reducing paper jams and improving print resolution. For instance, expert analyses show that paper structured with pre-coat layers experiences fewer interruptions during printing, allowing for smoother operations and less downtime. Case studies from demanding print settings also demonstrate the effectiveness of these layers in maintaining high-quality output, supporting their adoption across industries that rely heavily on precision and efficiency in their printing tasks.

Top Coat Innovations for Fade Resistance

Recent innovations in top coat technologies drastically improve the fade resistance of printed images on thermal paper. These coatings have been shown to extend the longevity of prints in real-world applications, such as outdoor signage and receipts that require durability against environmental wear. According to consumer feedback, the effectiveness of fade-resistant coatings significantly enhances branding by preserving the clarity of printed images even under harsh conditions. This technology not only extends the lifespan of printed materials but also boosts consumer confidence in the quality and reliability of thermal paper products.

Core Material Optimization for Printer Compatibility

Optimizing core materials has become essential for improving compatibility with various thermal printers and enhancing user experience. This optimization ensures that thermal papers interact seamlessly with printers, resulting in smoother operation and fewer technical issues. Statistical evidence points to higher efficiency rates and improved printer performance when optimized core materials are used. Businesses have reported increased operational efficiency as a direct result of these advancements, demonstrating that enhancements in core material design lead to tangible improvements in the usability and performance of thermal paper in diverse printing environments.

Product Showcase: Cutting-Edge Thermal Paper Solutions

Thermal Paper Permanent Hotmelt Adhesive Blue Glassine

Thermal Paper Permanent Hotmelt Adhesive Blue Glassine stands out for its versatile applications in the industry. It features an all-temperature adhesive that ensures excellent adhesion across various substrates, making it ideal for food and medical labels. This adhesive showcases impressive die-cutting and stripping characteristics, contributing to its usability in challenging conditions. Users often highlight its medium initial tack, which is advantageous for labeling small bottles and other delicate applications.

TDS Thermal Paper 3F Removable Glue for Logistics

TDS Thermal Paper 3F offers a unique removable glue technology, making it a staple in logistics applications. This innovative adhesive is particularly beneficial for retail information labels and furniture discount labels, providing operational flexibility and economic advantages. The removable glue solution is advantageous in varying environments, although care must be taken to avoid peak temperatures and specific substrates like PVC.

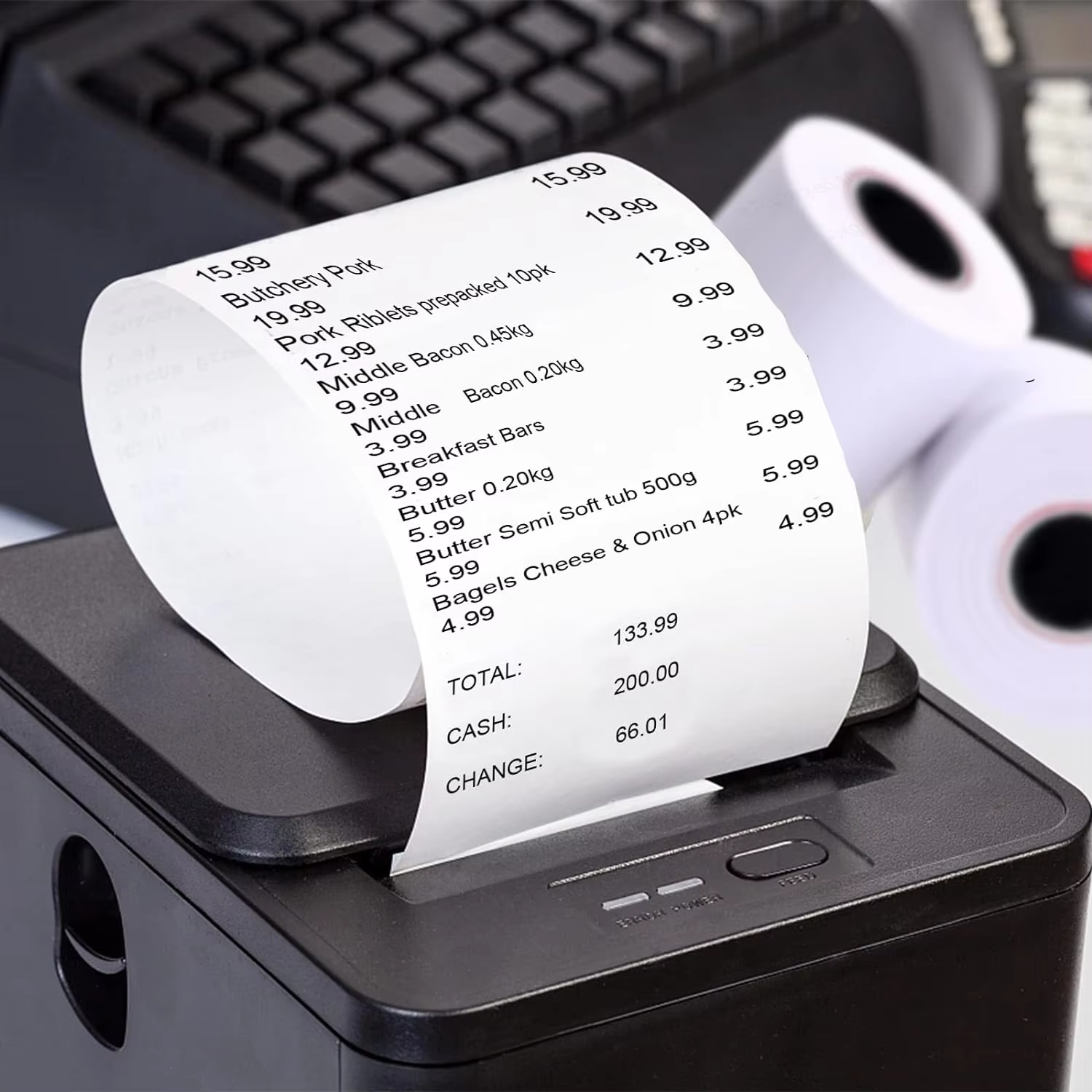

Factory-Direct ATM/POS Thermal Receipt Rolls

Securing thermal receipt rolls directly from the factory provides quality assurance and substantial cost benefits for ATM and POS applications. These rolls, typically made from 100% wood pulp, are customizable and available in various sizes, ensuring they meet specific usage requirements. Market analyses frequently highlight the consistency in quality and pricing that factory-direct sourcing offers, making it a strategic option for businesses focused on efficiency and savings.

Customizable Waterproof Thermal Paper Without Liner

Customizable Waterproof Thermal Paper Without Liner is engineered for specialized applications needing durability against moisture without a liner. It excels in environments requiring removable adhesive capabilities, such as electronic scale and barcode printer labels. Feedback from the industry points to the paper's customizable nature and adaptability in various environmental settings as critical advantages, though it must avoid prolonged exposure to heat and humidity to safeguard imaging quality.

High-Speed Die-Cutting Thermal Labels for Retail

High-speed die-cutting thermal labels have revolutionized retail efficiency, providing faster processing and consumer satisfaction. Innovations in label manufacturing ensure these labels meet retail industry demands with ease, incorporating enhanced adhesive properties that streamline application processes. Businesses report marked improvement in operational performance, suggesting these labels contribute significantly to both customer service and employee productivity, underscoring their transformative impact across retail settings.

By showcasing these innovative products, companies can stay at the forefront of thermal paper solutions, meeting diverse demands across industries—from logistical labels to retail efficiency boosters.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

ID

ID

SR

SR

SK

SK

SL

SL

SQ

SQ

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

MK

MK

UR

UR

BN

BN

LA

LA